We offer clients with a complete range of high-end quality packaging containers and sustainable packing solutions for the global cosmetic & skincare brand market.

COLOR MATCHING & DECORATIONS

Color Matching

We will use Pantone color codes to achieve color consistency and accuracy between pump heads, closures and bottles.

However, there may be some variation in the same color code due to differences in production processes, materials and suppliers, and we will try to keep the color variation within acceptable tolerance.

Light, middle and dark color range board will be provided for customers with strict color requirements.

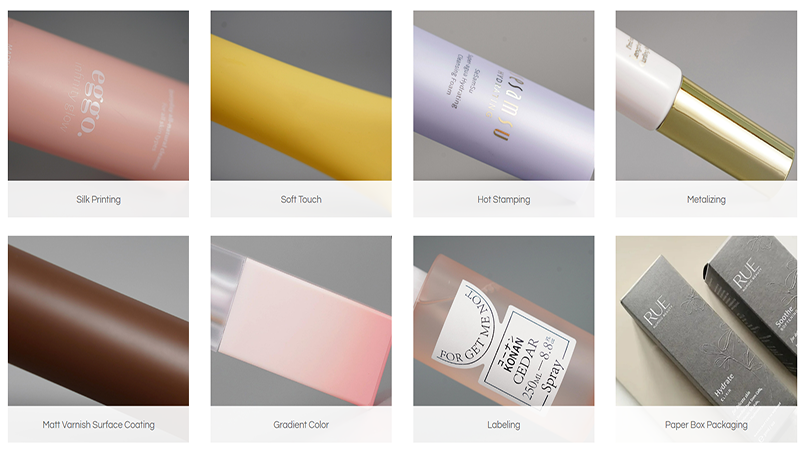

Decorations

There are various decorations for bottles and tubes, which will enhance the visual appeal of your product.

Silk printing, Matte finish, Soft touch, Hot stamping, Gradient effect, Labeling, Embossing/debossing, Coating.

Flexible matching for pumps and bottles

Our team is experienced in providing consultation and advice on selecting the best combination of pumps and bottles based on the customers’ requirements, with a rich amount of suppliers for different kinds of packaging items, we are able to give your products a more exclusive look

We strive to provide a one-stop solution that is reliable, efficient, and cost-effective. Our flexible matching services can help customers save time and effort in searching for the perfect combination of pumps and bottles, ensuring the final product meets your expectations.

SHORT PRODUCTION AND SAMPLING TIME

Bulk production generally takes 30-35 days, sampling takes 7-10 days.

Ready to Ship for stocks

we understand the importance of being able to ship out products quickly and efficiently. That’s why we offer ready-to-ship services for some of our stock items, including regular glass bottles and jars, and standard airless bottles.

We offer low MOQ for stock goods, and can arrange for door-to-door shipping to provide you with a hassle-free way of receiving the goods.

3D PRINTING AND MOCK UP

For the product that needs mold development, we can make 3D samples, which help visualize and test a new product’s design, size and function, before it goes into mass production.

This can help save time and money in the long run, as it reduces the need for expensive and time-consuming mold revisions.

CUSTOMIZED MOLDING SERVICE

Customized molding service is a manufacturing service that offers customized solutions for customers’ unique product designs.

We have experienced engineers and technicians who have expertise in product design and manufacturing. They can provide guidance and support throughout the manufacturing process, from initial design to final production.

Quality Assurance

We take pride in having a good quality control system in place to ensure we consistently deliver high-quality products to our customers.

A pre-production sample must be provided to customers for confirmation before mass production.

During the manufacturing process, controls are put in place to ensure that the items are being produced right in every manner, these controls may include in-process inspections, quality checks, and testing.

After production, the products will be visually inspected to ensure that they are free from defects such as scratches, dents, or discoloration.

Cosmetic containers, such as bottles or jars, may be tested to ensure that they are leak-proof, child-resistant, and tamper-evident. This testing ensures that the containers meet the necessary safety standards.

All products will be packed with standard export cartons, some items, such as glass containers, will be packed on pallets and make sure no damage during transit.

SUSTAINABLE PACKAGING SOLUTIONS

Sustainable packaging solutions are becoming increasingly important as consumers and businesses seek to reduce their environmental impact, below is our specific solutions to achieve sustainability:

1. Biodegradable Packaging: which is made from natural renewable materials, such as cornstarch, sugarcane, and wood, that can break down and decompose in the environment.

2. Recyclable Packaging: which is made from materials that can be recycled, such as glass, metal, or made of PCR plastic, which is up to 100%.

3. Reusable Packaging: which can be used multiple times, reducing the need for new packaging materials. This includes refillable bottles and jars.

Our TEAM IS READY TO GIVE YOU THE SERVICES YOU NEED.

Allow Ruispack, a young and creative company, to assist you in improving quality, brand image, and personalization, achieving genuine ROI and increasing sales, lowering trade costs expenditures, and improving clients’ shipping experience.